Printed Circuit Board Upgrades

Howman Engineering provides Printed Circuit Board upgrade services to re-engineer obsolete boards. An old PCB may require redesign to bring the product to current standards, replace hard-to-find and obsolete parts, update embedded processors, add new features or functions or to reduce material and labor costs - including Thru-Hole to Surface Mount (SMT) Conversion.

Howman Engineering’s design team evaluates your current PCB, analyzing the layout, function and operation of your board. For the majority of boards, our team can use this analysis to upgrade your PCB even if you no longer have Gerber data or PCB artwork.

We re-engineer boards for modern manufacturing techniques including Design for Manufacturability (DFM). Howman Engineering’s DFM process minimizes your re-engineering costs and ensures the smooth transition of your redesigned prototype into full-volume production. We support your product with revised CAD files and complete documentation for production. Most importantly, the final design is owned by your company.

CASE STUDY:

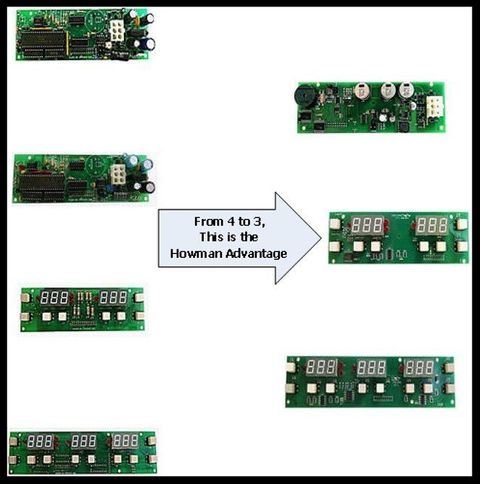

FROM 4 to 3 - THE HOWMAN ADVANTAGE

A Howman Engineering customer had a set of four thru-hole printed circuit boards, two with an obsolete processor. The customer boards consisted of two separate but similar processor boards and two display boards. Securing a supply of obsolete processors on the open market would significantly increase production costs and decrease availability.

Howman Engineering took the initiative and re-engineered the boards for our customer.

THE HOWMAN ENGINEERING SOLUTION

Howman Engineering’s design team evaluated the four boards, analyzing their layout, function and operation. In the re-engineering process, Howman Engineering reduced the set of 4 printed circuit boards to 3 boards.

The two display boards were redesigned to use mostly surface mount components instead of the former thru-hole. The two processor boards were combined into a new single surface mounted board to be used across both display platforms.

Howman Engineering’s re-engineering of the boards lowered our customer’s manufacturing costs and enhanced our ability to support the product set into the future.

Contact Howman

Address

291 US Highway 22, Ste. 40

Lebanon, NJ 08833

Mon - Fri: 8 am - 6 pm EST

Our Mission

Howman Engineering is committed to ethical business practices. It starts with leadership, from owner to management, exhibiting and exemplifying ethical principles. Howman Engineering interacts with our employees, our customers and our suppliers in a fair and professional manner. It shapes the way we view our environment, our local and global communities. It includes the ongoing process of improving our products in the areas of energy efficiency, cost control and sustainability.